— 4 min read

How to Use a Crane Lift Plan (With Free Template)

Last Updated Mar 5, 2025

Anthresia McWashington

Content Manager

20 articles

Anthresia McWashington is a Content Manager at Procore. She previously worked as an editor and reporter for Gulf Energy Information and Houston Media Group. She earned her BA in Communications and Journalism from the University of Houston. Anthresia loves track & field and practicing her French. She lives in Houston.

Last Updated Mar 5, 2025

Many construction projects require moving heavy materials, equipment and assemblies. These lifting operations depend on load-handling equipment (LHE) like cranes and derricks that are designed to relocate suspended construction components vertically and horizontally.

Any time large machinery like a crane enters a jobsite, a wide range of factors comes into play that introduce risks. In addition to endangering the health and safety of onsite crews, cranes can pose serious hazards for the construction site, surrounding property, other machinery and the load being hoisted.

This article lays out the fundamentals of what a crane lift plan is, what it includes, different types of plans and a free crane lift plan template that can cover all the bases before any crane starts its engine.

Table of contents

Understanding Crane Lift Plans

Also called a prelift plan, lifting plan or lift plan, a crane lift plan is a document containing all the details about a crane’s activity on a construction project. The main purpose of the plan is to mitigate risk and loss by improving safety for all onsite workers. Crane lift plans can also minimize delays and cost overruns by keeping all equipment, materials and property intact. A crane lift plan should be completed and distributed before any load is raised or moved.

A crane lift plan is typically devised and written by the lift director. In addition to creating the crane lift plan, lift directors are also responsible for preparing the work area, addressing any safety concerns and ensuring compliance when working near power lines or lifting personnel.

According to Occupational Safety and Health Administration (OSHA) regulation Part 1926 Subpart CC, employers are mandated to appoint a qualified person to act as lift director. In this context a qualified person means they must earn a qualification from the state, city and/or a national trade association such as the National Commission for the Certification of Crane Operators.

Standard Lift plans

Standard lift plans (also called simple or non-critical) refer to straightforward single-crane operations. They are largely left up to the discretion of the employer or site supervisor. For example, when a contractor arranges to unload procured materials.

Critical Lift plans

In 2019, the American Society of Mechanical Engineers (ASME) responded to the increasing complexity of lifting operations with the P30.1 standard for special engineered or critical lifts. OSHA defines a critical lift as one that exceeds 75% of the rated capacity of the crane or derrick, or requires the use of more than one crane or derrick.

10 Components of a Crane Lift Plan

Much like site-specific safety plans (SSSPs), crane lift plans are tailored to the project site’s parameters. These plans should include information about the crane’s load characteristics, including weight, dimensions and center of gravity, to ensure the selection of appropriate lifting equipment.

Additionally, the crane lift plan should address any environmental factors like wind speed and ground conditions onsite, as these can significantly impact lifting operations. It’d also be helpful to include a map of the site’s layout, including any obstacles or proximity to power lines to prevent accidents. At a minimum, crane lift plans should include the following 10 components.

- Project: Owner, location, general contractor, etc.

- Crane: Capacity, boom length, radius, etc.

- Cribbing: How the crane will be supported while lifting

- Assembly: Specs on erecting and, if applicable, dismantling the crane

- Load: Description, weight, dimensions

- Crew: Lift director, site supervisor, rigger, signalperson

- Communications: The use of hand signals, radios, phones, etc. while lifting

- Hazards: Physical constraints, environment, weather, power lines, etc.

- Sketch: A diagram of the crane’s position, crew and load

- Documentation: qualifications, maintenance logs, inspections, etc.

Unlike annual crane inspection reports, crane lift plans are not always mandated in the U.S. While they are strongly recommended to support safety initiatives on all lifting operations, distinctions should be made to determine whether regulatory guidelines apply.

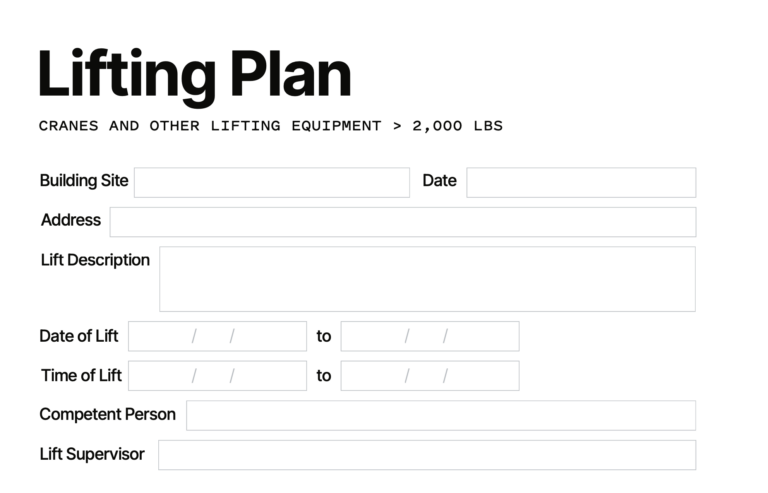

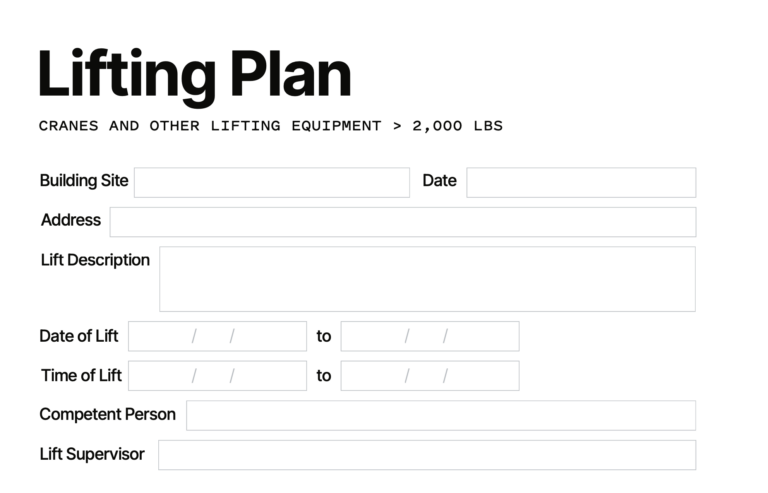

Download a Crane Lift Plan Template

Free Download

Crane Lift Plan Template

This ready-to-use free crane lift plan template can be downloaded and customized for any project.

- Free starter template

- Reuse on multiple projects

- Created by construction professionals

Crane Lift Plans Help Safeguard Operations

In addition to minimizing physical and material risks, crane lift plans can increase efficiency and productivity across construction projects. By developing realistic pre-lift scenarios, these plans help site leaders to identify potential challenges and develop solutions in advance.

Crane lift plans provide safety teams with a structured framework that helps avoid delays and missteps during operations. They can also create a sense of safety and preparedness, reducing the likelihood of accidents and downtime. When implementing safety measures beyond the required standards set forth by regulating bodies, construction sites can achieve higher standards of performance.

Was this article helpful?

Thank you for your submission.

100%

0%

You voted that this article was . Was this a mistake? If so, change your vote

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Thank you!

You’re signed up to receive The Blueprint newsletter from Procore. You can unsubscribe at any time.

Categories:

Written by

Anthresia McWashington

Content Manager | Procore

20 articles

Anthresia McWashington is a Content Manager at Procore. She previously worked as an editor and reporter for Gulf Energy Information and Houston Media Group. She earned her BA in Communications and Journalism from the University of Houston. Anthresia loves track & field and practicing her French. She lives in Houston.

View profileExplore more helpful resources

6 Tips to Turn Construction Culture Into Daily Practice

Every construction company has a culture. Whether it’s intentional or not. The difference lies in how that culture shows up on the job. In the first article of this series on...

Turning Values into Workflows: How a GC Firm Operationalized Culture

Culture isn’t just about what companies believe — it’s about how those beliefs show up in day-to-day work. When culture is embedded into operations, it becomes something teams can rely...

How a Successful GC Firm Turned Personalities into Culture

The culture at Ryan Gootee General Contractors (RGGC), a successful construction firm based in New Orleans, was never something the company had to invent. It was always there. Woven into...

Rise of the Super-Sub: Mastering Supply Chain & Logistics for Offsite Construction

Modern construction projects come with ever-increasing demands. Owners want to see more complex builds completed on tighter schedules. At the same time, general contractors (GCs) face challenges like the ongoing...

Free Tools

Calculators

Use our calculators to estimate the cost of construction materials for your next project.

Templates

Find a template to help you with your construction project tasks.

Material Price Tracker

Get the latest U.S. retail prices and view historical trends for common building materials.

Glossary

Explore key terms and phrases used in the industry.