— 4 min read

How to Build an Effective Construction Logistics Plan (With Free Template)

Last Updated Mar 20, 2025

Anthresia McWashington

Content Manager

20 articles

Anthresia McWashington is a Content Manager at Procore. She previously worked as an editor and reporter for Gulf Energy Information and Houston Media Group. She earned her BA in Communications and Journalism from the University of Houston. Anthresia loves track & field and practicing her French. She lives in Houston.

Last Updated Mar 20, 2025

It’s no secret that efficiently running a construction site requires intentional planning. Behind each successful project lies a detailed construction site logistics plan (CLP) that is dedicated to making sure projects are safe, cost-effective and running smoothly.

In this guide, we'll explore how to create an effective construction logistics plan and provide a customizable template that can be tailored for various projects.

Table of contents

Key Aspects of a Construction Logistics Plan

Not to be confused with a construction management plan, a construction logistics plan is the framework to manage the movement, storage and use of resources onsite. The goal behind each plan should be to:

- Reduce inefficiencies and waste

- Optimize resource and personnel allocation

- Make sure supplies are delivered on time and within budget

How to Create an Effective Construction Logistics Plan

A strong CLP outlines how to manage materials, equipment and workforce efficiently while anticipating challenges and addressing site-specific needs. This guide outlines a step-by-step approach to help project managers and planners create a flexible and effective logistics plan.

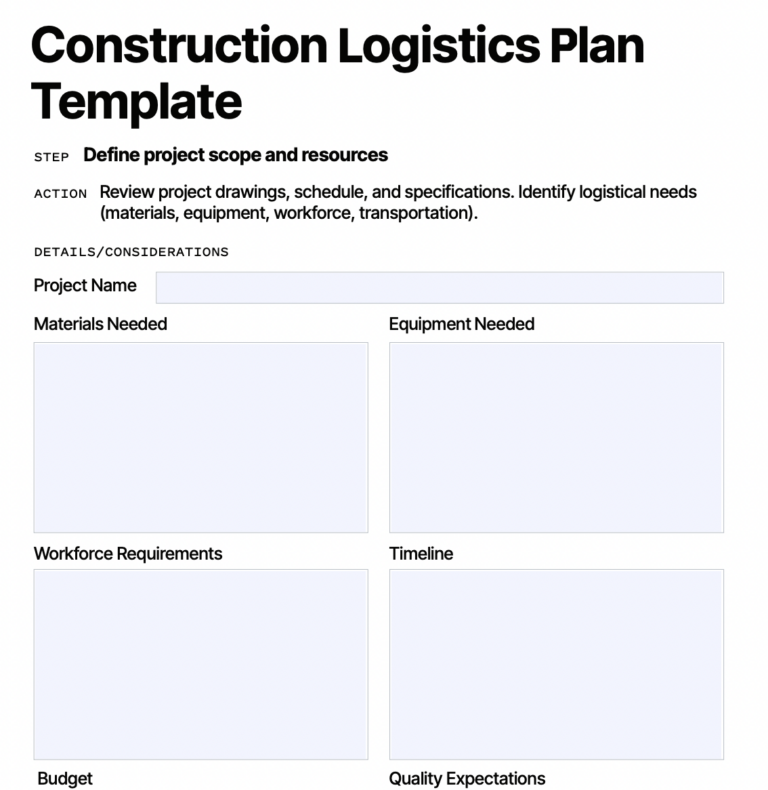

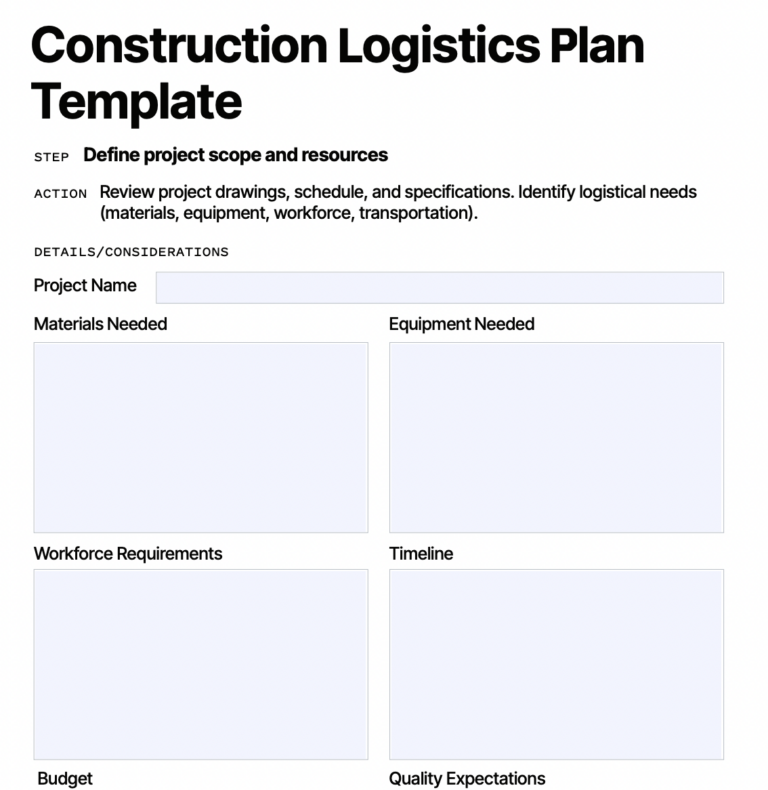

Define project scope and resources.

The project manager reviews the project’s drawings, schedule and specifications to understand the scope. They define logistical needs like materials, equipment, workforce and transportation, and set realistic expectations for the timeline, budget and quality.

Assess site layout and conditions.

The project team evaluates the site layout to plan for material access, storage and movement. They also consider local conditions like weather, traffic or regulations to ensure logistical efficiency.

Plan deliveries and storage.

The project team collaborates to create a delivery timeline so materials and equipment arrive as needed to avoid delays. They also designate material storage areas to keep things organized and set up an inventory tracking system to monitor deliveries and reorder levels.

Coordinate equipment and workforce.

The project manager identifies what equipment and workforce will be needed at each stage. They make sure both are scheduled and available when required to avoid unnecessary downtime and keep the work on track.

Set up safety, security and emergency plans.

The project manager outlines safety protocols for handling materials, equipment and site activities. They designate supervisors for compliance, secure storage areas and map emergency routes in coordination with local authorities.

Optimize traffic flow and site efficiency.

The project team should also plan for material unloading and staging areas to be away from active work zones to reduce congestion. They should also prioritize options to optimize traffic flow within the site and surrounding areas to minimize disruptions and improve efficiency.

Document and communicate the plan.

The logistics plan is documented with schedules, access routes, material handling protocols and safety measures. Visual aids like maps and diagrams clarify the plan, and the project manager shares regular updates with the team and stakeholders so everyone is aligned.

Free Download

Construction Logistics Plan Template

This easy-to-use fillable PDF template can help identify and organize any project's logistical needs.

- Free starter template

- Ready-to-use

- Designed especially for construction

Tips for a Successful Construction Logistics Plan

To maximize construction site logistical efficiency, consider these key strategies to help stay organized and adaptable throughout the project.

Use technology for better communication, visibility and control.

According to a Prologis report on supply chain outlook, cloud-based supply chain management platforms and real-time inventory systems are key players in logistics. Leveraging technology during logistics planning can streamline your operations and minimize delays.

- Use cloud-based tools to centralize communication, project updates and document management.

- Implement real-time inventory management systems to track materials, equipment and deliveries.

- Consider adopting GPS tracking and geofencing tools to manage fleet movements and ensure efficient logistics flow.

Plan for material, equipment and labor availability.

As supply chains continue to change, it helps to plan for potential disruptions. While reshoring efforts are improving supply chain reliability, logistics plans should still account for potential delays. Construction project teams should:

- Work with local suppliers to reduce reliance on international shipments and mitigate potential delays.

- Include buffer time in the schedule for possible disruptions, such as material shortages or transportation issues.

- Regularly reassess labor availability and adjust scheduling as needed to prevent delays caused by workforce shortages.

Schedule deliveries during off-peak hours.

A significant number of deliveries may occur during peak hours, which can lead to congestion and delays. To help keep a project on track, consider the following:

- Plan major deliveries during early mornings or late afternoons to avoid heavy traffic.

- Coordinate with suppliers and transporters to make sure they can accommodate off-peak delivery times.

- Monitor traffic patterns and adjust times as necessary to guarantee smooth site access and prioritize just-in-time deliveries.

Stay updated on what’s happening in construction.

Subscribe to Blueprint, Procore’s free construction newsletter, to get content from industry experts delivered straight to your inbox.

Move Forward With an Effective CLP

A well-made construction logistics plan can be the difference between a smooth, efficient project and one filled with delays and complications. Having a clear plan to follow provides a framework that is accessible to key players and can be tailored to meet the unique demands of the project.

Was this article helpful?

Thank you for your submission.

0%

0%

You voted that this article was . Was this a mistake? If so, change your vote

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Thank you!

You’re signed up to receive The Blueprint newsletter from Procore. You can unsubscribe at any time.

Categories:

Written by

Anthresia McWashington

Content Manager | Procore

20 articles

Anthresia McWashington is a Content Manager at Procore. She previously worked as an editor and reporter for Gulf Energy Information and Houston Media Group. She earned her BA in Communications and Journalism from the University of Houston. Anthresia loves track & field and practicing her French. She lives in Houston.

View profileExplore more helpful resources

6 Tips to Turn Construction Culture Into Daily Practice

Every construction company has a culture. Whether it’s intentional or not. The difference lies in how that culture shows up on the job. In the first article of this series on...

Turning Values into Workflows: How a GC Firm Operationalized Culture

Culture isn’t just about what companies believe — it’s about how those beliefs show up in day-to-day work. When culture is embedded into operations, it becomes something teams can rely...

How a Successful GC Firm Turned Personalities into Culture

The culture at Ryan Gootee General Contractors (RGGC), a successful construction firm based in New Orleans, was never something the company had to invent. It was always there. Woven into...

Rise of the Super-Sub: Mastering Supply Chain & Logistics for Offsite Construction

Modern construction projects come with ever-increasing demands. Owners want to see more complex builds completed on tighter schedules. At the same time, general contractors (GCs) face challenges like the ongoing...

Free Tools

Calculators

Use our calculators to estimate the cost of construction materials for your next project.

Templates

Find a template to help you with your construction project tasks.

Material Price Tracker

Get the latest U.S. retail prices and view historical trends for common building materials.

Glossary

Explore key terms and phrases used in the industry.