— 12 min read

How to Prepare for Final Building Inspection (With Free Checklist)

Last Updated Dec 6, 2024

James Hamilton

Writer & Producer

85 articles

James Hamilton is a writer based in Brooklyn, New York with experience in television, documentaries, journalism, comedy, and podcasts. His work has been featured on VICE TV and on The Moth. James was a writer and narrator for the show, VICE News Tonight, where he won an Emmy Award and was nominated for a Peabody Award.

Dave Brown

Product Success Manager

9 articles

Dave is a Product Success Manager at Procore. Previously, he worked for Consigli Construction Co in Boston and Washington, DC as a Project Engineer and Assistant Project Manager, responsible for a variety of activities including bidding and procurement, contracts, and cost control. Dave holds a Bachelor's Degree in Structural Civil Engineering from Bucknell University.

Ernest Garcia

Ernest Garcia is a Solutions Engineer at Procore. Prior to joining the construction tech industry, Ernest worked as a project manager and superintendent, overseeing large-scale healthcare and government construction projects across the U.S. He's successfully completed projects for the United States Air Force, Department of Energy, Army Corps of Engineers, Los Alamos National Laboratories, and Border Patrol. Outside of work, he enjoys all things outdoors, metal fabrication and woodworking, and spending time with his family and dogs. He lives in Glendale, AZ.

Last Updated Dec 6, 2024

The closeout process for a commercial construction project is the culmination of an incredible amount of planning and labor. This is particularly true for one of the last steps of closeout: the final inspection.

The final inspection is an inspection by a local zoning authority or building department to make sure a building fully complies with local codes, usage regulations, and safety requirements. The final inspection is usually the last requirement for obtaining a certificate of occupancy and is done after all work has been completed, permits have been closed, and other inspections have been conducted.

In this article, we will take a look at how to prepare for a final inspection, what building inspectors usually look for, and common things that could go wrong.

Table of contents

The Importance of the Final Inspection

Passing a final inspection is a crucial part of keeping closeout on schedule and on budget. Because a final inspection takes place after work is done, addressing major issues — such as faulty wiring that’s covered up by walls — can be extremely time-consuming and expensive.

The final inspection is meant to check the safety of buildings that have been newly constructed, converted to a different usage classification, had major renovations, or are changing ownership. The inspection is done by a licensed inspector from the local building authority who will check for compliance to codes and laws that weren’t reviewed in other inspections, such as the placement of address numbers, as well as making sure all issues from other inspections, like electrical or plumbing, have been resolved.

Passing the final inspection is almost always a requirement for obtaining a certificate of occupancy (CO) and closing all work permits, both steps that must be completed if the owner ever wants to sell the building. A CO is required in most places for a building to be used at all. For contractors, obtaining a CO is often connected to receiving final payment or retainage.

How to Prepare for a Final Building Inspection

Preparing to pass a final inspection is a long process that requires diligence throughout the construction process. It starts when designers submit building plans to the local building authority, which only approves plans if they comply with codes and laws. Those plans must then be followed at every stage of construction by builders and subcontractors.

While that might sound intimidating, there are a few things that general contractors can always do to prepare for a final inspection.

Pass Previous Inspections

Before a final inspection can even be conducted, the building must first pass a number of other, smaller-scale inspections that are required to close specific work permits. These inspections are done at strategic times during construction to make addressing issues manageable. Some work permits require an inspection while work is in progress, often called a rough or rough-in, and another when it’s done. For example, many places require a rough electrical inspection when the building is partially done and electrical boxes are in place, and a final electrical inspection when all work is done and walls have been put up. Some places, like Nassau County in Florida, will provide different checklists for the rough electrical and the final electrical.

These prerequisite inspections should ensure there are no surprises at the final inspection, and passing them should mean the building is already up to, or nearly up to, code. It’s important to check with the local building authority to see which inspections are needed. Some inspections are extremely specific, such as lowest floor elevation inspections which are required for buildings in flood hazard areas such as Scottsdale, Arizona.

Some places, like Montgomery County, MD, will provide lists of all potential inspections and what each one will focus on. Which ones are required depends on the building and where it’s located. Here are common types done before a final inspection:

- Foundation and footing

- Mechanical

- Electrical

- Plumbing

- Framing

- Soil

- Roof

- Insulation

- Lath and/or Gypsum

- Steel

- Masonry

- Energy efficiency

- Walls

- HVAC

- Fire safety

Schedule the Final Inspection

Picking the right time for the final inspection is important, because it should happen after all work is done and before applying for the certificate of occupancy. Local building authorities vary in how quickly they are able to do inspections based on their size and workload, so it’s always better to reach out well in advance.

Many building departments require calling their office. Other places have adopted an online booking calendar, such as Prince William County in Virginia.

Ask What to Expect

Many building authorities or inspectors will provide a list of focus areas before the inspection, with the hope that the building will be ready and all issues will already be addressed, though this isn’t required. Contractors can ask for a checklist when scheduling the inspection or find a detailed list on the website of some municipalities, such as Washington County in Oregon. We will also provide a general checklist below.

Roles and Responsibilities in Executing Final Inspections

Most of the work at the final inspection is done by the inspector who is licensed and works for the local zoning or building authority, but multiple parties take part. Let’s take a look at what other people can do to help make the inspection a success.

General contractor

The general contractor is usually the party responsible for scheduling the final inspection, though this can be done by a superintendent or a foreman depending on the size of the project. The person who scheduled the inspection should be in attendance and should come with documentation, ready to answer questions or address concerns from the inspector.

Much of the GC’s work is done before the final inspection. From the very beginning of construction, they ensure all steps required to close permits, pass a final inspection, and obtain a certificate of occupancy are included in the project’s plans and critical path schedule. As the contractor manages the logistics of the jobsite, they should provide progress updates on these milestones in meetings with the owner and architect. This helps to minimize any surprises that might arise at the final inspection.

Design team

At this point, the design team should hopefully have no work left to do, assuming their plans complied with code and were followed by all builders. Most of the issues an inspector might find can be addressed without someone from the design team, such as adding an extra exit sign or attaching a cover plate while a light fixture is ordered. However, there are occasionally bigger issues that can impact cost and require approval, such as a room that needs more electrical outlets. In this case, the designers might be called in by the client and general contractor to help address the issue.

Owner’s Representative

The owner or an owner’s representative is often allowed to be present at a final inspection, but this is usually just to make sure the inspection happens and to understand any issues. They should not intervene or attempt to alter the inspection.

Creating a Final Building Inspection Checklist

The areas and issues of focus for an inspector vary depending on the type of building and the local building code.

Many checklists, like this one from Austin, Texas, can be found by checking the website of a local building authority or contacting them directly. Some checklists, such as this one from Tampa, Florida, sort checklist items by systems, like electrical, mechanical, or natural gas.

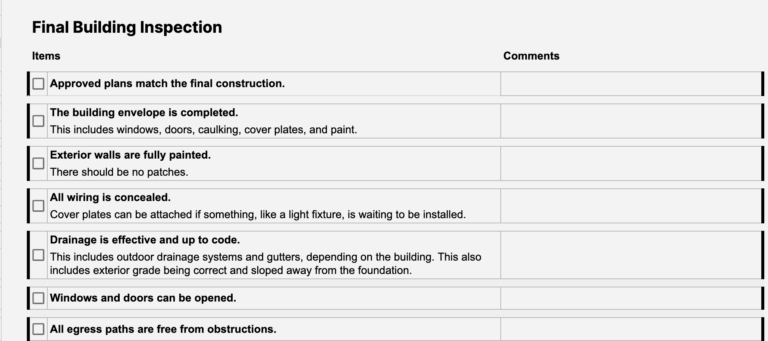

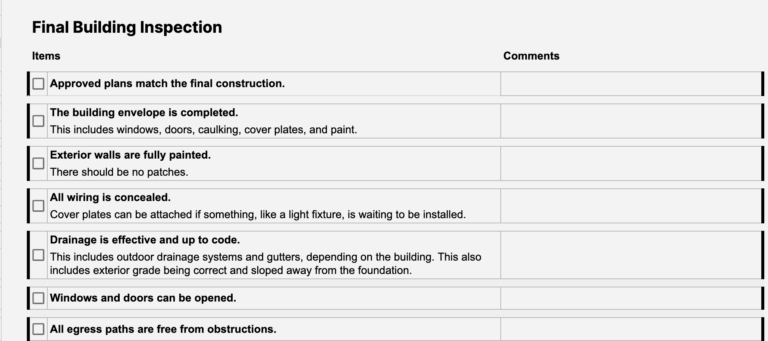

Free Download

Final Building Inspection Checklist

Use this final building inspection checklist to create a personalized list of inspection items. It includes suggested elements inspectors have an eye out for as well as spaces to add project-specific items.

- Free template

- Ready-to-use with space for customization

- Created by construction professionals

Here is a list of things that inspectors are commonly looking for:

- Approved plans match the final construction. If they don’t, the inspector can ask for the building to be altered or for a revised plan of the finished building to be submitted.

- The building envelope is completed. This includes windows, doors, caulking, cover plates, and paint.

- Exterior walls are fully painted. There should be no patches.

- No wiring is exposed. Cover plates can be attached if something, like a light fixture, is waiting to be installed.

- Drainage is effective and up to code. This includes outdoor drainage systems and gutters, depending on the building. This also includes exterior grade being correct and sloped away from the foundation.

- Windows and doors can be opened.

- All egress paths are free from obstructions.

- Right-of-way sidewalk is in place and unhindered.

- Parking striping and signs are in place.

- Handrails and guardrails for stairs are in place and have the correct clearance..

- Building address numbers are visible and the correct size. Size varies based on location, but are usually around 4 inches for a residential building and 6 inches for a commercial building. The address is usually required to be visible from the road, either on the building or on signage.

- The building is accessible to people with disabilities. These requirements are outlined by the ADA.

- Mechanical, electrical, and plumbing is up to code and issues from previous inspections have been addressed.

- Insulation is up to code and issues from previous inspections have been addressed.

- The HVAC system is working and issues from previous inspections have been addressed.

- Smoke alarms, strobes, and sprinklers are in place and can be tested. Rings are on sprinkler heads and the heads are not painted.

- Exhaust fans, hoods, etc. are in place and can be tested.

- Required exits are in place and unhindered. This includes exit access doorways, exit access stairways or ramps, or any combination.

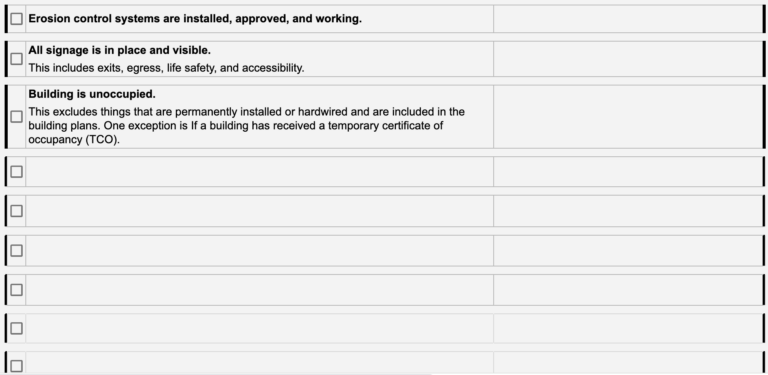

- Erosion control systems are installed, approved, and working.

- All signage is in place and visible. This includes exits, egress, life safety, and accessibility.

- Nothing was moved into the building. This excludes things that are permanently installed or hardwired and are included in the building plans. One exception is If a building has received a temporary certificate of occupancy (TCO).

Common Issues Found During Final Inspections

There are so many elements being assessed during a final inspection that it’s possible for any number of issues to come up, such as faulty wiring, leaky plumbing, or improper framing. A common issue is a building not meeting the standards of the Americans with Disabilities Act (ADA).

Issues can range from easy-to-fix problems — like adding a sign to an exit door that says “This door to remain unlocked when this space is occupied” — to something major, like soil settling and causing the foundation to crack. However, most issues shouldn’t be much of a surprise, since final inspections come after other inspections and general contractors generally check the building themselves numerous times.

One of the most common issues is when a building’s final construction doesn’t match the building plans approved at the beginning of construction. This could include a room having the wrong number of outlets, a handrail having the wrong clearance, or a window not meeting egress requirements.

The contractor must assess how easily and affordably this issue can be addressed. Some inspectors will suggest a solution that is manageable and keeps the process moving, but issues that pose a life safety risk will need to be thoroughly and urgently addressed. In the case of a major discrepancy that doesn’t pose an immediate safety risk, a contractor might be able to submit a revised building plan of the final construction to the municipality.

What if a project fails final inspection?

The severity of a failed final inspection depends on the severity of the issues identified. Usually, a general contractor will be able to make plans to resolve the problem and schedule another inspection, although this will likely require another inspection fee and more time.

A delay in passing a final inspection can cause a delay in obtaining a certificate of occupancy. Prolonged delays in obtaining a CO can result in the building owner losing money since the building isn’t able to fulfill its intended use. In worst-case scenarios, the general contractor may end up having to pay liquidated damages.

Final Building Inspections Best Practices

Like much of the closeout process, streamlining the final inspection process requires a lot of time, work, and organization. There are a few things that can almost always help do this.

Document Everything

Extensive documentation is one of the best ways to make sure that, no matter what question an inspector might have or whatever issue they might find, a contractor is prepared with an answer. Documentation always includes formal documents, like building plans or proof of passing other inspections, but it should also include taking photos throughout the construction process. This is especially true for things that are installed behind a wall or in the floor or ceiling.

Digital tools, such as Procore’s document management, are extremely helpful for organizing documents, being strategic with what to document, and tracking progress.

Create Organizational Systems

Projects that take a long time and involve a lot of people require even more communication, logistics, and paperwork. There are advanced tools, such as Procore’s Action Plans tool, that can help track permits, drawings, submittals, and correspondence, and can be made visible to a client to help them gain an understanding of a project’s progress.

Plan ahead

The closeout process can be extensive and elaborate, so contractors should always be looking forward and leaving room in the schedule for potential slowdowns.

Stay updated on what’s happening in construction.

Subscribe to Blueprint, Procore’s free construction newsletter, to get content from industry experts delivered straight to your inbox.

Maintain a Positive Relationship with Inspectors

Many inspectors are licensed to do more than one type of inspection, so it’s common for a contractor to work with the same person more than once through the inspection process. Inspectors work to stay impartial and fair, but they are often under a lot of pressure to do many, highly intricate inspections every day.

Cultivating a positive relationship with an inspector through clear and respectful communication can mean the inspector might be more likely to help problem-solve or provide insight when issues arise.

The Long Road to a Final Inspection

Final inspections can be an incredibly stressful part of closeout, simply because of how many variables are at play and how much work goes into preparation. Being diligent and organized at every step of the construction process will help, but a contractor should always take time to become familiar with a building authority’s specific requirements and what to expect from a final inspection to make sure it isn’t a chaotic part closeout, but is instead smooth and triumphant.

Was this article helpful?

Thank you for your submission.

90%

10%

You voted that this article was . Was this a mistake? If so, change your vote

Scroll less, learn more about construction.

Subscribe to The Blueprint, Procore’s construction newsletter, to get content from industry experts delivered straight to your inbox.

By clicking this button, you agree to our Privacy Notice and Terms of Service.

Thank you!

You’re signed up to receive The Blueprint newsletter from Procore. You can unsubscribe at any time.

Categories:

Written by

James Hamilton

Writer & Producer

85 articles

James Hamilton is a writer based in Brooklyn, New York with experience in television, documentaries, journalism, comedy, and podcasts. His work has been featured on VICE TV and on The Moth. James was a writer and narrator for the show, VICE News Tonight, where he won an Emmy Award and was nominated for a Peabody Award.

View profile

Dave Brown

Product Success Manager | Procore Technologies

9 articles

Dave is a Product Success Manager at Procore. Previously, he worked for Consigli Construction Co in Boston and Washington, DC as a Project Engineer and Assistant Project Manager, responsible for a variety of activities including bidding and procurement, contracts, and cost control. Dave holds a Bachelor's Degree in Structural Civil Engineering from Bucknell University.

View profileReviewed by

Ernest Garcia

Ernest Garcia is a Solutions Engineer at Procore. Prior to joining the construction tech industry, Ernest worked as a project manager and superintendent, overseeing large-scale healthcare and government construction projects across the U.S. He's successfully completed projects for the United States Air Force, Department of Energy, Army Corps of Engineers, Los Alamos National Laboratories, and Border Patrol. Outside of work, he enjoys all things outdoors, metal fabrication and woodworking, and spending time with his family and dogs. He lives in Glendale, AZ.

View profileExplore more helpful resources

Preparing for Post-Construction: A Guide to the Final Phase of a Project

Large construction projects often take years to plan, more years to design, and even more years to build. From the groundbreak point of view, it’s often difficult to see the...

A Guide to Construction Commissioning

During project closeout, an owner wants to receive any documents, training and warranties needed to take over the management and maintenance of their building. But they also want assurance that...

Construction Handover: Keys to an Efficient Process

After the months or years it takes to complete a construction project, the handover process begins. Project handover is the final part of the construction process, where a project, along...

Construction Closeout Documents: What’s Included & Why

Few parts of the building process can feel as stressful and as complicated as closeout: the multi-step, final phase of construction in which a project is prepared to be handed...

Free Tools

Calculators

Use our calculators to estimate the cost of construction materials for your next project.

Templates

Find a template to help you with your construction project tasks.

Material Price Tracker

Get the latest U.S. retail prices and view historical trends for common building materials.

Glossary

Explore key terms and phrases used in the industry.