— 5 min read

Ctrl + Build: Running on Zero – Why Energy Efficient Data Centres Start with Design.

Last Updated Aug 28, 2025

Paul Acker

As a Strategic Product Consultant at Procore, Paul Acker boosts construction financials through expert Procore implementation and ERP integrations. He translates complex technical and financial problems into practical solutions, improving cash flow, reporting, and project margins for construction firms, developers, and subcontractors. Paul's blend of construction management, financial optimisation, and an MBA - backed by success leading multi-billion dollar system and data migrations - ensures technology delivers tangible commercial results and drives efficiency.

Nicholas Dunbar

Content Manager

65 articles

Nick Dunbar oversees the creation and management of UK and Ireland educational content at Procore. Previously, he worked as a sustainability writer at the Building Research Establishment and served as a sustainability consultant within the built environment sector. Nick holds degrees in industrial sustainability and environmental sciences and lives in Camden, London.

Last Updated Aug 28, 2025

As power-hungry data centres multiply, builders must play a bigger role in reducing emissions by digitally tracking every delivery milestone.

The age of AI is here — and it runs on data. A lot of data.

Every chatbot, video stream, crypto transaction and Internet of Things sensor feeds the global appetite for processing power. That means more data centres.

Table of contents

More Data, More Demand

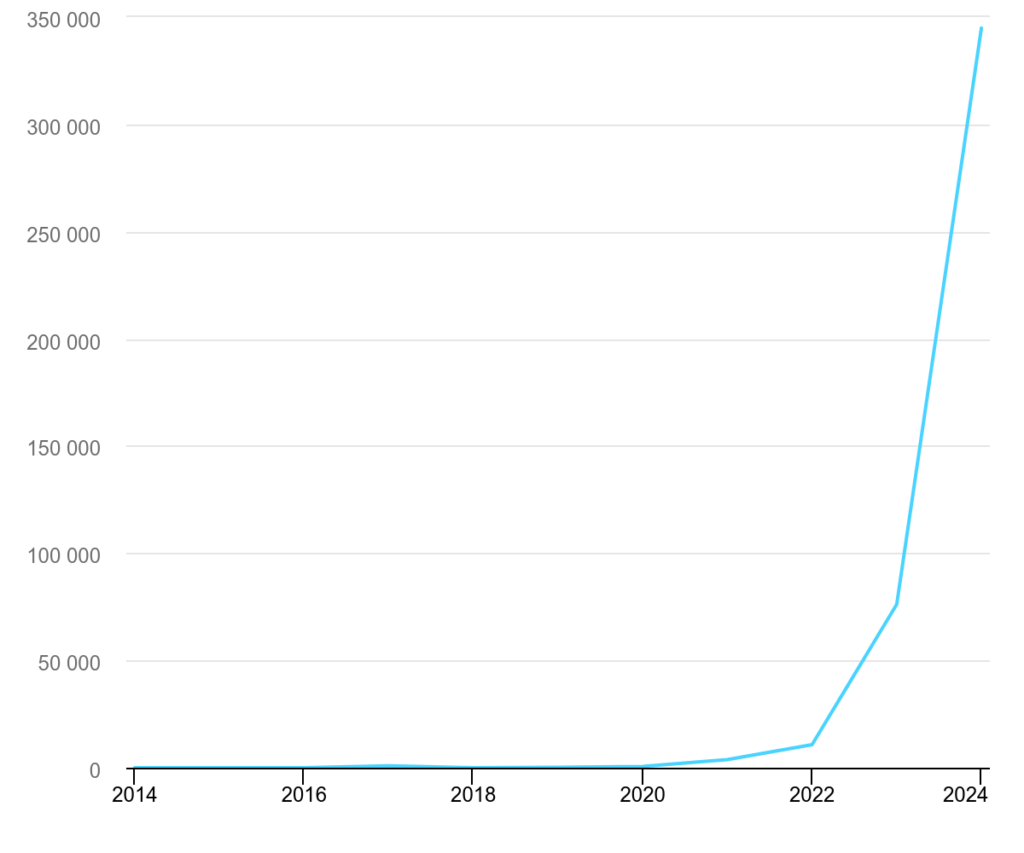

According to Savills, across Europe, installed data centre power capacity is forecast to rise by roughly 27 per cent to around 13 GW by 2027, with the UK on course to see its capacity almost double by 2028.

Closer to home, data centres already draw about 2 per cent of Great Britain’s electricity; the National Energy System Operator warns this share could quadruple by 2030.

The story is similar around the world. Globally, electricity use from data centres, crypto and AI could double by 2026 – exceeding 1,000 terawatt-hours. The International Energy Agency (IEA) warns that’s more than the entire electricity consumption of Japan.

This growth puts pressure on delivery teams to scale faster, with less margin for inefficiency.

The business model of data centre delivery is speed. But some of the sector’s challenges – emissions, grid strain, embodied carbon – are much slower to solve.

Paul Acker

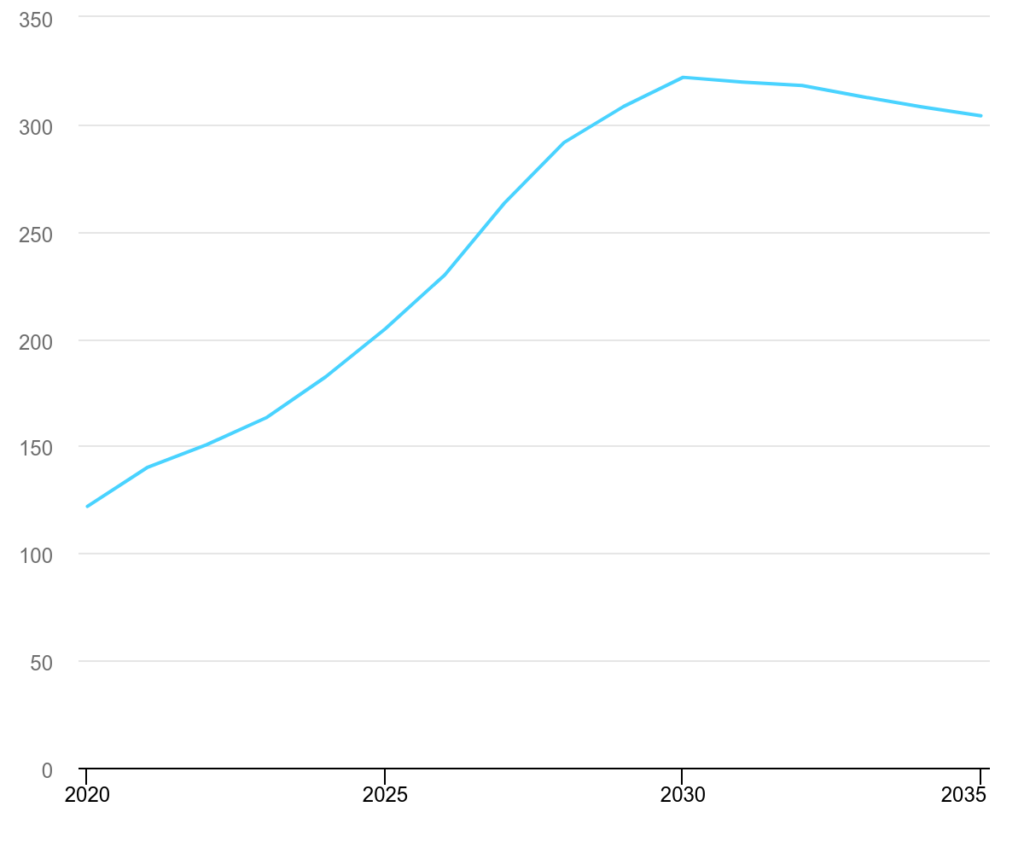

Global Data Centre Carbon Emissions, 2020-2035

Source: International Energy Agency, 2025.

Here are just a few statistics from the IEA that have data centre operators burning the midnight oil:

- 100,000 households – the equivalent electricity that a typical AI-focused data centre consumes. The largest ones under construction today will use 20 times as much.

- 12% annual growth – the rate at which data centre electricity consumption has increased globally since 2017 - more than four times faster than overall electricity demand.

- 10x more capital-intensive – an AI-focused data centre compared to an aluminium smelter.

- 20% of demand growth – the share of electricity demand growth that data centres now represent in advanced economies, where total energy demand has otherwise remained flat.

- 1 in 5 projects – the proportion of global data centre builds now facing risk of delay due to grid connection bottlenecks.

Then there’s the other environmental impacts. Around 40% of the average facility’s power is spent on the crucial task of cooling. Cooling the rows and racks of powerful computers requires up to 19 million litres of water a day – similar to the quantity of water consumed by 50,000 people.

Every one of these statistics translates to tighter specs and higher performance expectations for delivery teams.

Data Centre Electricity Consumption

Source: International Energy Agency, 2025.

Why Net Zero Matters for Builders

More than 60% of the world’s biggest companies are moving towards net zero emission – and that means assessing every element of their carbon footprints.

While data centre operators are under pressure to decarbonise, their ability to meet these expectations increasingly depends on the supply chain. Builders must now support delivery models that meet lower-carbon expectations, provide emissions transparency and enable smarter decisions during construction.

Currently, 36% of data centre operators collect Scope 1 emissions data, and fewer still report on Scope 2 or Scope 3. We are seeing improvements, fast, with robust emissions tracking and project-level reporting soon to become table stakes.

The message is clear: builders who can provide emissions data and support net zero outcomes are more likely to be chosen as preferred partners.

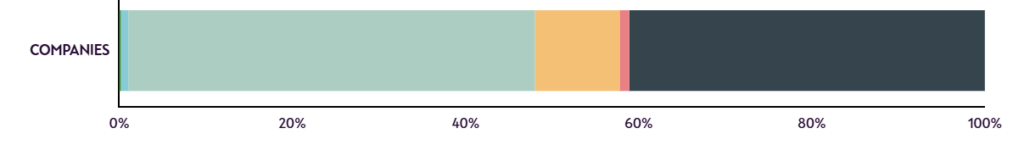

Net Zero Corporate Commitments, 2025

Source: Net Zero Tracker, 2025.

An analysis of the the world's largest 2,000 publicly listed companies by annual revenue showed the following commitment to net zero targets:

- 0.19% (4 companies) achieved, externally validated

- 0.87% (18 companies) achieved, self declared

- 47% (974 companies) in corporate strategy

- 9.8% (203 companies) pledged

- 1.1% (23 companies) proposed

- 41% (852 companies) no net zero target

The Overlooked Emissions Footprint

Energy efficiency – and environmental impact more broadly – isn’t just an operational issue for data centres. It is a core design challenge for constructors and contractors – and that makes it a delivery risk.

From grid connections to cable trays, sequencing to installation, construction teams play a critical role in how efficiently a facility performs. The systems they install, the quality of that install, and the way it’s verified all shape emissions outcomes.

Quality assurance systems must evolve. Digital inspection workflows and structured documentation aren’t just about compliance, but about capability.

Renewables, Ratings and the Road Ahead

There’s good news. Data centre operators are pivoting fast.

Many major providers (and their customers) have committed to 100% renewable energy by 2030. These commitments are backed by renewable energy power purchase agreements (PPAs). Globally, 45% of all renewable PPAs now involve data centre operators, according to some estimates. This is a clear signal of the sector’s growing role in accelerating the energy transition.

In the UK, BREEAM-certified data centres show how the business case stacks up: moving from a ‘Good’ to an ‘Excellent’ rating typically cuts energy use by over 30 per cent, saving millions in running costs.

The takeaway here?

Energy performance is flowing through contracts, checklists and reporting – and that means it is a construction deliverable, not just an operational aspiration.

Lifting Visibility Across Every Site

Some project teams are beginning to integrate carbon tracking and energy workflows into a single source of truth. Using Procore-based quality assurance and commissioning workflow supports:

Smart, sustainable delivery starts with visibility. If you want a greener footprint, you need a clearer picture

Paul Acker

- Embodied carbon tracking for steel, concrete and major plant

- Grid access timelines integrated into the build schedule

- Commissioning templates linked to energy modelling

- Shared dashboards for owner oversight across all sites.

The most forward-looking teams are already adapting. Those who lead on energy will lead on trust, delivery and future work.

Categories:

Written by

Paul Acker

As a Strategic Product Consultant at Procore, Paul Acker boosts construction financials through expert Procore implementation and ERP integrations. He translates complex technical and financial problems into practical solutions, improving cash flow, reporting, and project margins for construction firms, developers, and subcontractors. Paul's blend of construction management, financial optimisation, and an MBA - backed by success leading multi-billion dollar system and data migrations - ensures technology delivers tangible commercial results and drives efficiency.

View profileReviewed by

Nicholas Dunbar

Content Manager | Procore

65 articles

Nick Dunbar oversees the creation and management of UK and Ireland educational content at Procore. Previously, he worked as a sustainability writer at the Building Research Establishment and served as a sustainability consultant within the built environment sector. Nick holds degrees in industrial sustainability and environmental sciences and lives in Camden, London.

View profileExplore more helpful resources

Integrated Compliance: A Main Contractor’s Guide to ISO 9001, 14001, 45001, and 44001

For UK main contractors, ISO 9001, 14001, and 45001 are fundamental prerequisites to any tendering activity. The Building Safety Act, Net Zero targets, and tight margins mean these certifications are...

The Main Contractor’s Action Plan for Commercial Risk

For UK main contractors, managing risk protects project margins, rather than solely acting as a compliance exercise. Construction is an industry defined by thin profits and high liability, and a...

Construction Action Plans: Minimising Risk & Maximising Delivery

A construction project is a complex set of tasks, resources, and stakeholders. Without a clear, documented path forward, even meticulous planning can lead to delays, cost overruns, and disputes. The...

Construction Drawings: Guide to Types & Regulations

While architects, urban planners and landscape designers first conceive buildings and public realms in their minds, translating vision into detailed drawings remains the foundation for any project. Construction drawings translate...