— 8 min read

A Guide to Construction Risk Assessments in the UK

Last Updated Aug 28, 2025

Samantha Nemeny

33 articles

Sam—Samantha if she’s feeling particularly academic—has spent a decade in content marketing, with eight years focused on Australia’s construction industry. She has a knack for making complex ideas easy to understand, turning industry jargon into clear, engaging stories. With a background in SEO and marketing, she’s spent the past three years at Procore, helping industry professionals navigate the world of construction with content that’s both insightful and easy to digest.

Nicholas Dunbar

Content Manager

65 articles

Nick Dunbar oversees the creation and management of UK and Ireland educational content at Procore. Previously, he worked as a sustainability writer at the Building Research Establishment and served as a sustainability consultant within the built environment sector. Nick holds degrees in industrial sustainability and environmental sciences and lives in Camden, London.

Last Updated Aug 28, 2025

Construction is one of the United Kingdom’s most dynamic industries, driving economic growth, shaping skylines and creating essential infrastructure. But with opportunity comes risk. From worker safety to cost pressures and regulatory compliance, project teams must navigate a complex landscape to keep construction sites safe, efficient and legally sound.

In 2023/24, the Health and Safety Executive (HSE) recorded 45 fatal injuries to construction workers - nearly twice the five-year average for all industries - highlighting the need for stronger safety measures. Labour shortages and rising costs continue to impact project viability, while new regulations such as updates to Part L of the Building Regulations and the ongoing evolution of the Construction (Design and Management) Regulations 2015 (CDM 2015) are reshaping compliance requirements.

A well-structured construction risk assessment is one of the most effective ways to manage these challenges. By identifying, evaluating and mitigating risks, project teams can enhance safety, maintain compliance and improve overall project outcomes.

In this guide, we consider the role that risk assessments play in UK commercial construction projects, and how to implement a practical risk-assessment process. Whether you’re a project manager, contractor or developer, understanding how to conduct effective risk assessments will help you build safer, more resilient projects.

Table of contents

What is a Construction Risk Assessment?

A construction risk assessment is a systematic process used to identify, evaluate and mitigate risks that could impact a construction project. Its goals are to:

- Identify potential hazards and risks

- Determine who or what may be affected

- Eliminate or reduce risks where possible

- Increase awareness of existing and potential risks

- Ensure compliance with legal and regulatory requirements

Under the Health and Safety at Work etc. Act 1974, every duty-holder must eliminate or control risks “so far as is reasonably practicable”. In addition, Regulation 3 of the Management of Health and Safety at Work Regulations 1999 makes written risk assessments mandatory where five or more people are employed. The HSE enforces these duties and can issue Improvement Notices, Prohibition Notices or significant fines.

By proactively managing risks, teams can prevent delays, control costs and improve project outcomes. While safety hazards often come to mind, risk assessments go beyond physical dangers - they also help assess financial risks, compliance risks and other factors that impact a project's success. For instance, an owner may conduct a financial risk assessment to evaluate potential cost overruns, market risks or funding uncertainties.

The Importance of Risk Assessments

CDM 2015 requires risks to be controlled in a specific order (the hierarchy of control). Using a structured risk-assessment process helps ensure compliance and reduces the risk of breaches. For example, when managing height-related risks, implementing edge protection and fall-prevention systems not only protects workers but also ensures adherence to HSE standards.

Risk assessments enable teams to identify and address potential hazards before they escalate into costly or dangerous issues. They also serve as a strategic tool that helps teams anticipate project delays, budget overruns and regulatory challenges, ensuring that projects run smoothly from start to finish. Ultimately, a robust risk-assessment process nurtures a safety-first culture - boosting morale and helping firms win repeat work.

Key Types of Risk Assessments in Construction Projects

Understanding the types of risks in construction helps you implement effective mitigation strategies. They can be categorised into five main areas.

| Safety Hazards The primary goals of safety risk assessments is to ensure worker safety and minimise accidents. These assessments focus on identify risks such as: | Falls from heights—particularly in high-rise and scaffold-heavy construction Vehicle and machinery accidents—especially on tight urban worksites Heat stress and dehydration—common in remote and high-temperature areas Exposure to hazardous materials—such as silica dust, asbestos, and lead-based products |

| Financial Risks Financial risk assessments aim to keep projects within budget and ensure profitability | Cost overruns—due to fluctuating material costs, especially concrete, timber, and steel Insolvency of key contractors or suppliers—a common issue in the construction industry Rework and defect rectifications—especially on projects rushed to meet state-funded deadlines Inflation and rising labour costs—due to the UK's high demand for skilled trades |

| Project-Management Risks The goal of project management risk assessments is to adhere to the project timeline and meet contractual obligations | Programme delays—caused by weather events such as flooding, and droughts Poor coordination—between local subcontractors and international suppliers Inadequate documentation—leading to non-compliance with regulatory audits Delays in approvals—due to complex processes from state and local government authorities |

| Environmental & Regulatory Risks Environmental and regulatory risk assessments are designed to maintain compliance with legislation and regulations. | Water pollution Non-compliance with Part L Environmental-impact delays Noise and dust pollution |

| Supply chain and workforce risk assessments ensure that teams have access to skilled workers and necessary materials, minimising delays and cost overruns. | Material shortages—caused by global supply chain disruptions, especially with steel and timber Volatility in material prices—due to import dependency and logistics issues Quality control issues—with non-compliant imported materials such as steel and cladding Delays in workforce availability—due to strict border controls affecting international skilled workers |

How to Perform a Risk Assessment

Performing an effective construction risk assessment is essential for ensuring safety, efficiency and compliance. Here are the key steps.

Risk Identification

The first step in the process is to identify all potential risks that could affect the project.

This can be done through:

On-site inspection checklists: Regular site inspections help spot hazards and assess conditions.

Data from similar past projects: Drawing on past experiences provides insights into common risks.

Consultation with contractors, subcontractors and HSE representatives: Gathering input from people involved in the project helps to uncover overlooked risks.Risk Analysis

Once risks have been identified, each one should be analysed based on its likelihood and impact. To evaluate a risk, ask the following questions:

How likely is this risk to occur?

How severe would the consequences be if the risk occurs?

For example:

A major structural failure in a high-rise might have low likelihood but high impact.

A minor supply delay for non-essential materials may be highly likely but have a minimal impact.

A fall from height in a multi-storey project has a high likelihood and a severe potential impact.Risk Evaluation and Prioritisation

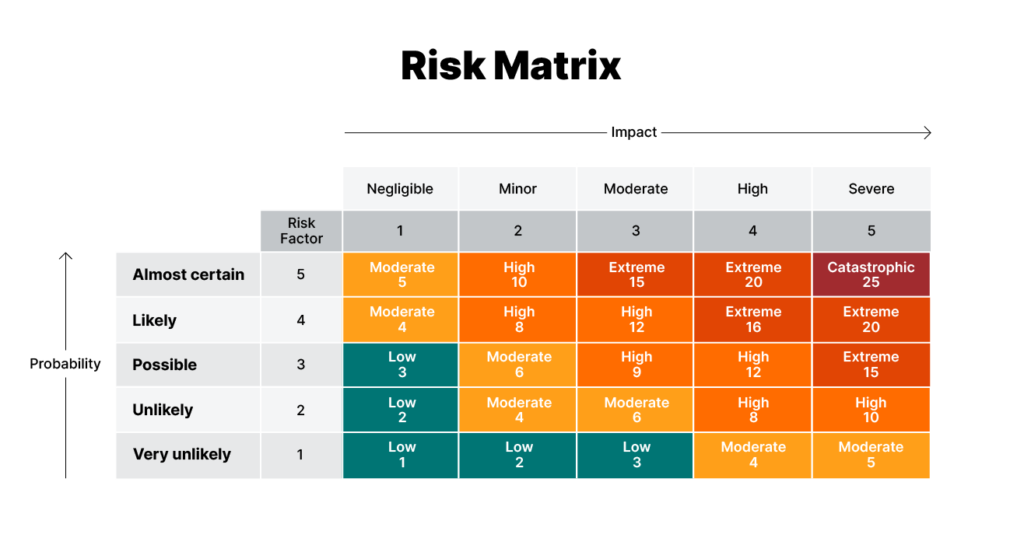

Not all risks need immediate attention. After identifying and analysing the risks, you should prioritise them based on their likelihood and severity using a risk matrix.

This step helps determine which risks need immediate mitigation efforts and which can be monitored. Once the risks are ranked, focus on mitigating those with the highest priority (those that are rated Very High).Risk Mitigation Strategies

For each risk, identify appropriate mitigation strategies to reduce, transfer, or eliminate it. Common strategies include:

Engineering controls: For example, installing edge protection systems to prevent falls.

Administrative controls: Enforcing strict site safety protocols and ensuring contractor compliance.

Insurance and financial safeguards: Securing contract clauses that protect against supplier insolvency.Ongoing Monitoring and Review

Risk assessments are not a one-time task. Risks should be continually monitored and reassessed throughout the project lifecycle.

Regular site inspections: Check for new or emerging hazards.

Audits and compliance checks: Ensure the project is meeting regulatory standards and safety protocols.

Dynamic risk assessments: Reassess risks whenever conditions change, such as when a new contractor is brought on-site, regulations shift, or new machinery is introduced.

By continuously reviewing and updating your risk assessments, you can ensure that the project remains on track and risks are addressed proactively.

Most principal contractors package the assessment with a Method Statement - together known as a RAMS (Risk Assessment & Method Statement) - to show exactly how each control will be implemented on site and who is responsible.

Leveraging Technology for Real-Time Risk Tracking and Reporting

Incorporating digital tools into risk assessments is crucial for real-time tracking and reporting. These tools enable site workers and managers to log hazards via mobile devices, centralise data and maintain accurate records for regulatory compliance.

Modern construction technology offers:

- Predictive risk analytics to anticipate issues before they escalate

- Automated compliance tracking to reduce human error

- AI-driven safety monitoring for real-time hazard detection

Platforms like Procore give project teams a single source of truth - reducing rework, driving data-backed decisions and mitigating risk at every project stage.

Modern construction technology makes risk identification and mitigation itself easier, with advanced functionality like:

- Predictive risk analytics: Uses historical data and machine learning to identify patterns and anticipate potential risks before they escalate, often catching possible risks before a human could.

- Automated compliance tracking: Continuously monitors construction activities to ensure they meet regulatory and safety standards, reducing human error and oversight gaps.

- AI-driven safety monitoring: Leverages artificial intelligence to detect hazards, monitor worker behaviour, and enhance on-site safety in real-time.

When is a risk assessment required on a UK construction site?

Risk assessments are not a one-and-done affair; they should be carried out at various stages of the project.

Before the Project Begins

- During planning and design

- When reviewing construction methods, materials and site conditions

Before High-Risk Activities

- Working at heights

- Excavation, heavy lifting and demolition

After Site Conditions Change

- Introducing new equipment or materials

- Following significant weather events

After a Process Change

- New work methods or design modifications

Following an Incident or Near Miss

- Any workplace accident or near-miss event

Regularly, as Part of Compliance and Safety Protocols

- Daily or weekly site inspections

- Before major project phases

- As required by the HSE

Build Resilience Through Proactive Risk Management

Construction risk assessments are vital for ensuring safety, efficiency and compliance throughout a project’s lifecycle. By systematically identifying, evaluating and mitigating risks - and by leveraging technology to maintain real-time oversight - construction teams can protect their workforce, meet regulatory obligations and deliver successful projects on time and within budget.

Ultimately, proactive risk management ensures that projects are completed successfully, delivering high-quality results while maintaining safety and regulatory standards. By prioritising risk assessments and embracing innovative solutions, construction professionals can confidently combat challenges and build resilient, future-proof projects.

Categories:

Written by

Samantha Nemeny

33 articles

Sam—Samantha if she’s feeling particularly academic—has spent a decade in content marketing, with eight years focused on Australia’s construction industry. She has a knack for making complex ideas easy to understand, turning industry jargon into clear, engaging stories. With a background in SEO and marketing, she’s spent the past three years at Procore, helping industry professionals navigate the world of construction with content that’s both insightful and easy to digest.

View profileReviewed by

Nicholas Dunbar

Content Manager | Procore

65 articles

Nick Dunbar oversees the creation and management of UK and Ireland educational content at Procore. Previously, he worked as a sustainability writer at the Building Research Establishment and served as a sustainability consultant within the built environment sector. Nick holds degrees in industrial sustainability and environmental sciences and lives in Camden, London.

View profileExplore more helpful resources

Integrated Compliance: A Main Contractor’s Guide to ISO 9001, 14001, 45001, and 44001

For UK main contractors, ISO 9001, 14001, and 45001 are fundamental prerequisites to any tendering activity. The Building Safety Act, Net Zero targets, and tight margins mean these certifications are...

The Main Contractor’s Action Plan for Commercial Risk

For UK main contractors, managing risk protects project margins, rather than solely acting as a compliance exercise. Construction is an industry defined by thin profits and high liability, and a...

Construction Action Plans: Minimising Risk & Maximising Delivery

A construction project is a complex set of tasks, resources, and stakeholders. Without a clear, documented path forward, even meticulous planning can lead to delays, cost overruns, and disputes. The...

Construction Drawings: Guide to Types & Regulations

While architects, urban planners and landscape designers first conceive buildings and public realms in their minds, translating vision into detailed drawings remains the foundation for any project. Construction drawings translate...