Related Articles

— 10 min read

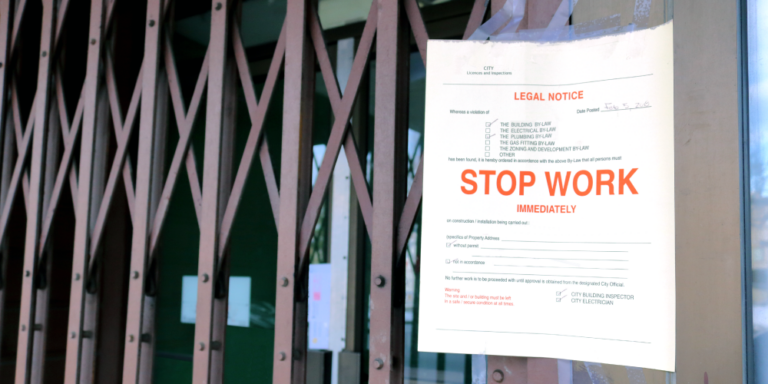

Understanding a Stop Work Order: Causes, Consequences, and Compliance Steps

Last Updated Aug 31, 2025

Samantha Nemeny

33 articles

Sam—Samantha if she’s feeling particularly academic—has spent a decade in content marketing, with eight years focused on Australia’s construction industry. She has a knack for making complex ideas easy to understand, turning industry jargon into clear, engaging stories. With a background in SEO and marketing, she’s spent the past three years at Procore, helping industry professionals navigate the world of construction with content that’s both insightful and easy to digest.

Last Updated Aug 31, 2025

A stop work order is becoming an increasingly common reality on Australian construction sites, as regulators, councils, and project owners take a harder line on safety, compliance, and quality control.

From unsafe scaffolding to unapproved structural changes, these legally binding directives can halt a project overnight, disrupt delivery schedules, and trigger significant financial exposure.

For experienced contractors, site managers, and project engineers, a stop work order isn’t just an operational pause—it’s a high-stakes test of leadership, governance, and problem-solving under pressure. Responding effectively requires a clear understanding of why these orders are issued, who enforces them, and the fastest path to reinstating work without compounding risks.

This article examines the triggers, enforcement processes, and resolution strategies for stop work orders in Australia, equipping teams to protect delivery certainty, uphold compliance, and minimise reputational and financial damage when work grinds to a halt.

Table of contents

What is a Stop Work Order?

A stop work order suspends specified construction activities until the underlying hazards or compliance breaches are resolved to the issuing authority’s satisfaction, protecting safety, limiting liability, and restoring legal compliance.

There are two primary types of stop work orders:

Full: halts all work on site

For example, a WHS inspector shuts down the entire site due to unsafe scaffolding.

Partial: suspends specific activities or areas only

For example, concrete pours are paused until approved formwork documentation is submitted, but other trades continue.

Why are Stop Work Orders Issued?

Authorities issue stop work orders when they can identify serious construction safety risks, legal breaches, or major contract violations that threaten the viability of a construction project and its on-site teams.

These orders apply to public and private projects and are enforceable under WHS legislation and contractual terms.

Common triggers include the following situations:

Safety Violations

Stop work orders are often used to control life-threatening hazards or high-risk tasks without compliant controls like:

- Performing high-risk activities without a Safe Work Method Statement (SWMS), such as working at height, live electrical work, confined space entry, or asbestos removal

- Unprotected edges or non-compliant scaffolding that create fall risks

- Mobile plant operating near workers or public access areas without proper controls

- Exposure to dust, noise, vibration, or airborne contaminants beyond safe thresholds

- Signs of heat stress, dehydration, or fatigue in the workforce

- Underground service strikes or unprotected excavations that create collapse risks

These issues have trickle-down effects and increase the likelihood of dangerous incidents. Without addressing and mitigating them head-on, owners can experience increased exposure to high insurance rates and troubles with workforce retention, among other impacts

Regulatory Breaches

Work may be suspended if the site operates without the required permits, fails to comply with the National Construction Code, or allows unlicensed trades to perform regulated tasks. If not immediately addressed, these breaches can result in legal action, fines, or project delays.

Engineering or Design Concerns

Projects may be halted due to:

- Structural design errors or omissions

- Use of incorrect materials

- Poor coordination between consultants or missing critical documentation

Production and Coordination Issues

Although less common, stop work orders may be issued when site activity becomes unsafe or unmanageable due to equipment breakdowns, supply delays, or unresolved clashes between trades. Poor sequencing can create unacceptable risk or stall progress across critical areas of the site.

Contractual or Financial Instability

When a contractor or subcontractor fails to meet key contractual obligations, or financial risks surface, regulators or head contractors may suspend works. This may involve:

- Disputes over payment

- Uncontrolled budget overruns

- Signs of insolvency or severe labour shortages

Environmental Compliance Breaches

Environmental authorities may stop work if the site breaches environmental regulations or disturbs protected habitats. Orders are typically issued until waterways, ecosystems, or soil integrity risks are addressed.

Who Can Issue a Stop Work Order?

In Australia, stop work orders can be issued by multiple authorities, from local councils to WHS inspectors, depending on the breach and the jurisdiction’s enforcement powers

Local Councils

Councils can halt construction for unauthorised works, permit breaches, or violations of local planning laws. These orders are typically issued under state-specific building legislation and enforced through compliance inspections.

State Building Regulators

Relevant state authorities, such as the NSW Building Commissioner for Sydney-based projects, can issue stop work orders to address hazardous construction defects.

For example, under the Residential Apartment Buildings (Compliance and Enforcement Powers) Act 2020, orders may be used to control high-risk developments such as residential high-rises.

Workplace Health and Safety Regulators

State WHS bodies (like WorkSafe QLD) can issue prohibition notices that act as stop work orders when unsafe practices present an immediate risk to health and safety. These are typically enforced on-site and remain effective until the hazard is fully controlled.

Environmental Regulators

Both state and federal environmental agencies may intervene if works breach ecological or environmental conditions or approvals. Orders are often issued to prevent unauthorised land disturbance, contamination, or ecosystem damage.

Project Owners

Where a construction contract includes a stop work clause, the principal may issue an order in response to breaches such as unresolved variations, unsafe practices, or a change in project scope. These actions must follow the terms and procedures set out in the contract.

What Does a Stop Work Order Include?

Stop work orders follow a consistent structure to ensure all parties understand what work must cease, why the order was issued, and how to achieve reinstatement. Clear documentation supports compliance and protects the project from further risk.

Typical elements include:

Project and Work Identification

Every order identifies the impacted site, scope, and trades, and states whether it applies to the entire project or specific zones or activities.

Reason for the Order

The order outlines the issue that triggered the stoppage. This may include permit breaches, regulatory violations, design flaws, or safety risks.

Corrective Actions Required

This section outlines the steps required to lift the order. It may involve updating documentation, rectifying defects, obtaining permits, or proving compliance. Where permitted, limited remedial work may continue during the stoppage.

Immediate Halt Requirement or Time Frame

Most orders require an immediate stop. Others may include a specific deadline or indicate that work is suspended until further notice.

Contact Details

The order includes contact information for the issuing authority, agency, or project representative responsible for enforcement and coordination.

Penalties and Legal Consequences

Failure to comply may result in additional penalties, including fines, prosecution, or extended site restrictions.

Immediate Steps to Take When an SWO Is Issued

Contractors must act immediately when a stop work order is issued to contain risk, maintain compliance, and avoid penalties. Prompt action also supports faster reinstatement and protects the contractor’s commercial position.

Cease Affected Work Immediately

Stop all work in the specified area or scope. Ignoring a stop work order may result in fines, prosecution, or site closure.

Review the Order Carefully

Confirm the scope, listed violations, corrective actions, and any conditions for permitted work. Misinterpreting the order may delay resolution or lead to further breaches.

Seek Clarification if Needed

Confirm all required corrective actions directly with the issuing authority to avoid scope misinterpretations that can prolong the stoppage.This may involve speaking with the site certifier, local council, WHS regulator, or environmental authority.

Engage Legal or Compliance Advisers

In complex or disputed situations, seek legal or compliance support early. Accurate advice helps prevent missteps and may reduce legal exposure.

Document Every Step

Maintain a detailed record of all actions taken, including receipt of the order, communications, cost impacts, and site changes. Use daily reports and site diaries to ensure traceability and support future claims

Begin Corrective Action Immediately

Resolve the underlying issue without delay. This may involve rectifying defects, updating documentation, applying for permits, or coordinating with subcontractors. Where possible, take steps to minimise costs associated with the work stoppage.

Consequences of Ignoring a Stop Work Order

Failing to comply with a stop work order exposes contractors and project owners to short- and long-term legal, financial, and operational risks. In most cases, the consequences far outweigh any perceived benefit of continuing unauthorised work.

Heavy Fines From Regulators

When scaffolding or structural safety is ignored, Australian regulators don’t hesitate. SafeWork inspectors have issued prohibition/stop-work directions for unsafe scaffolds on multiple NSW sites—over 500 to be exact—followed by hefty penalties for ongoing non-compliance.

The pattern is consistent: once a formal directive lands, continuing work drives fines up fast—daily or per-offence—especially for repeat breaches.

Forced Shutdown and Legal Escalation

A single order can shut down a high-traffic site and trigger broader enforcement.

Work ceases immediately in these incidents while further investigation proceeds, illustrating how WHS authorities and local councils impose significant monetary penalties for each day or instance of non-compliant activity. Fines vary by jurisdiction and offence type, with repeat or high-risk breaches attracting maximum penalties.

Project Delays, Cost Blowouts, and Rework

While not resulting from a “stop work order” notice, Victoria’s West Gate Tunnel Project ran into what an ABC News article called “standoff between Transurban, its builder John Holland CPB, and the state government over who will pick up the tab” when tunnelling halted for extended periods due to contaminated spoil and disposal constraints.

Instances like these show how significantly and swiftly regulator-driven stoppages can cascade into program drift, re-sequencing, and costly remediation. They’re a realistic proxy for the consequences of enforced stops that drag on: time is lost, costs compound, and rework piles up.

Furthermore, severe cases of unauthorised or non-compliant work may be demolished at the contractor’s expense, and ongoing breaches can lead to formal investigations or public enforcement notices.

Contract Termination and Loss of Insurance Coverage

Across multiple states, principals have terminated contracts “for cause” after significant safety or compliance failures led to regulator intervention and site shutdowns.

Insurers commonly exclude illegal or unauthorised works; once you’re operating under (or in defiance of) an order, coverage can narrow fast, leaving contractors exposed on defect rectification and delay claims.

Reputation and Relationship Damage

Public enforcement notices, especially those issued by state building regulators, linger. A stop work order that makes the news can sour relationships with councils, diminish tender shortlist chances, and make lenders and owners skittish.

The reputational dent often outlasts the rectification itself, and a record of non-compliance may limit future tender eligibility and erode trust across the supply chain.

Pro Tip

When a stop work order is issued, the head contractor carries responsibility for remediation. Even if a subcontractor’s work triggered the order, regulators will expect the principal party to rectify the issue.

How to Lift a Stop Work Order

To resume work legally and safely, contractors must follow a structured process to have the stop work order formally lifted. Each step should be documented and completed fully to avoid delays or further enforcement action.

Correct All Cited Violations

Comprehensively address the issue that triggered the order with actions such as, preparing a compliant Safe Work Method Statement, obtaining a missing permit, rectifying non-compliant work, resolving hazards

Document All Corrective Actions

Maintain clear records of the actions taken. Use dated photographs, inspection reports, updated permits, and safety documentation to verify compliance. Construction site diaries and daily reports should log each step and communication to support traceability and limit liability.

Notify the Issuing Authority and Request Re-Inspection

Once the issue is resolved, contact the relevant agency, inspector, or principal contractor to request a formal re-inspection. Allow time for scheduling and be prepared to review all corrective actions thoroughly.

Pay All Applicable Fines or Fees

Any outstanding penalties, inspection fees, or permit costs must be paid before the order can be lifted. Ensure that all required documentation is submitted as part of the process.

Obtain Written Clearance to Resume Work

This may come as a rescission notice, a compliance certificate, or a written direction from the authority that issued the order.

Stop work orders require immediate action and long-term accountability.

Stop work orders test a contractor’s ability to manage risk, protect delivery certainty, and recover quickly. Knowing the triggers, enforcement processes, and resolution steps allows leaders to act decisively, protect margins, and maintain regulator and client confidence.

Categories:

Written by

Samantha Nemeny

33 articles

Sam—Samantha if she’s feeling particularly academic—has spent a decade in content marketing, with eight years focused on Australia’s construction industry. She has a knack for making complex ideas easy to understand, turning industry jargon into clear, engaging stories. With a background in SEO and marketing, she’s spent the past three years at Procore, helping industry professionals navigate the world of construction with content that’s both insightful and easy to digest.

View profileExplore more helpful resources

What Construction Teams Need to Know About Warranties

As legally binding promises, construction warranties ensure that completed work meets the required standards of quality and performance for a defined period — and that’s why they must begin the...

Building Certainty with the Critical Path Method: Controlling Time, Cost, and Risk in Australian Construction

Australia is in the midst of a construction boom defined by complexity and scale. Multi-billion-dollar transport and energy megaprojects are reshaping cities and regional networks alike. But, as a study...

Substantial Completion in Construction: What Australian Contractors Must Know About Payment, Risk, and Handover

Substantial completion is the point where contractors must prove the asset is ready, owners must prepare to take control, and certifiers must be satisfied that every critical system can perform...

Understanding Retention in Construction Contracts: Australia’s Rules and Best Practices

Retention is becoming one of the most consequential financial pressures on Australian projects. As contractors manage larger workloads and tighter margins, withheld payments can erode liquidity, slow closeout, and increase...