— 10 min read

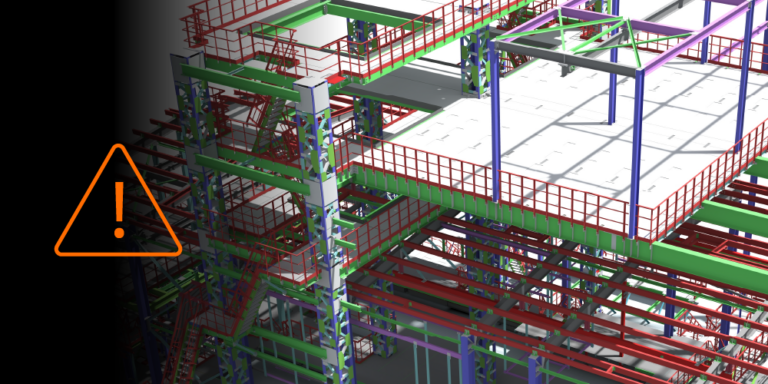

BIM Clash Detection: Reducing Rework, Delays, and Risk in Construction

Last Updated Dec 5, 2025

Josh Krissansen

55 articles

Josh Krissansen is a freelance writer with two years of experience contributing to Procore's educational library. He specialises in transforming complex construction concepts into clear, actionable insights for professionals in the industry.

Last Updated Dec 5, 2025

Design clashes can be a significant hidden cost in construction, as each conflict between systems risks expensive rework, project delays, and reduced margins. BIM clash detection empowers teams to identify and resolve issues before construction begins, enhancing cost certainty, schedule control, and on-site safety.

So it’s no surprise that the payoff for getting it right also translates to profitable gains.

On one major infrastructure project, effective clash detection and resolution delivered savings equivalent to around 20% of the total contract value, demonstrating that early coordination not only prevents problems but also enhances profitability.

This article examples how BIM clash detection improves design coordination, reduces rework and risk, and drives measurable financial performance across every stage of a project.\

Table of contents

What is BIM Clash Detection?

BIM (Building Information Modelling) clash detection is the process of identifying and resolving design conflicts within a combined digital building model before construction commences. As a proactive coordination method, it’s carried out during preconstruction using dedicated software.

Designers from various disciplines, including architecture, structural engineering, mechanical engineering, electrical engineering, and plumbing, each create their own models. These are combined into a federated model that allows teams to check for conflicts between systems.

For example, detecting a pipe intersecting a structural beam in the digital model enables the issue to be corrected early, preventing redesigns and delays during construction.

Roles and Responsibilities: Who’s Responsible for What

People in these two roles use BIM clash detection in different ways, but collaboration between them is critical to success. The BIM coordinator manages the process, while the design and trade teams resolve the conflicts identified in the model.

BIM Coordinator or BIM Manager

- Oversees the clash detection process by combining discipline models into the federated model

- Defines clash tests, runs analyses, and leads coordination meetings

- Tracks issue resolution and ensures the team follows the BIM Execution Plan

Design and Trade Teams

- Review and address clashes related to their scope of work

- Update their models to resolve conflicts under the coordinator’s direction

- Collaborate to ensure design adjustments are coordinated across all systems

How Clash Detection Elevates Project Performance and Profitability

BIM clash detection enhances performance across all key project drivers, including cost, time, quality, and safety. When teams resolve design conflicts early, they can deliver coordinated models that support smoother construction, stronger collaboration, and greater financial control.

Avoiding Rework and Delays

Identifying clashes in the digital model prevents last-minute design changes and costly rework. Issues fixed virtually take hours to resolve instead of days on-site.

In an analysis of one high-rise project, weekly coordination and cross-discipline model updates resolved 106 design conflicts before construction began, helping the team avoid about 45 days of potential delay.

Confidence in coordinated models also supports off-site prefabrication, reducing installation time and minimising on-site congestion. At the same time, fewer RFIs and faster approvals help maintain steady progress across all stages of the delivery process.Cost Control and Budget Confidence

Clash detection strengthens cost control by identifying design conflicts before procurement or fabrication. When components fit correctly from the start, teams limit variation costs, reduce contingency use, and protect project margins.

Coordinated BIM models also produce more accurate quantities and layouts, thereby improving cost forecasting during the preconstruction phase. Firms using proactive clash detection have reported six-figure savings through reduced rework and material waste.Improved Collaboration

Effective clash detection promotes collaboration between architecture, structure, and MEP disciplines. Regular coordination meetings build transparent communication and shared accountability between consultants and trades. This process eliminates design silos, leading to smoother project delivery and fewer coordination-related RFIs or technical queries.

Quality and Safety

A clash-free design produces a more constructible model that aligns with real-world site conditions.

Eliminating rework reduces on-site disruption, a common cause of workplace incidents under WHS standards. Consistent model coordination also supports quality assurance processes and safer installation sequencing.Efficiency and Schedule Certainty

When clashes are resolved in preconstruction, project sequencing becomes more predictable. Trades can work in parallel without interference, and materials arrive as planned with minimal adjustment.

Reliable coordination ensures schedule commitments are met, giving clients and contractors greater confidence in project delivery.

Types of Clashes in BIM

Not all clashes carry the same impact. Understanding the main categories helps teams prioritise issues and apply the right solutions before construction begins.

In Australian commercial projects, identifying these conflicts early prevents rework, delays, and safety risks in accordance with WHS standards.

Hard Clashes

Hard clashes occur when two or more components occupy the same physical space. For example, a steel beam intersecting a mechanical duct or a cable tray running through a plumbing line.

These are the most critical and easiest to detect through BIM software and are usually resolved first during coordination meetings.

Holder Construction demonstrated the value of early detection by identifying 35 such conflicts, avoiding about $190,000 in collision costs with only $60,000 invested in coordination technology.

Soft Clashes

Soft clashes involve clearance or tolerance issues, such as an electrical panel without enough working space in front or a pump positioned where technicians cannot safely access it. These may not stop construction, but can cause safety or maintenance problems later.

BIM coordinators can set clearance tolerances within the model to identify and correct these conflicts proactively.

Workflow Clashes

Workflow clashes relate to scheduling rather than geometry.

They occur when construction activities overlap or occur out of sequence, such as installing a wall before the plumbing behind it is complete, or when two trades are scheduled to work in the same zone simultaneously.

These issues are detected through 4D BIM, which links the 3D model with the project schedule, allowing sequencing adjustments to be made before work begins.

Coherence Clashes

Coherence clashes arise from data inconsistencies within the model, such as missing parameters or incorrect values. A light fixture entered without a circuit number or classification field is a typical example.

While less visible than physical conflicts, these issues can compromise data integrity and downstream coordination. Regular model audits and quality checks help identify and correct them.

How Does BIM Clash Detection Work?

BIM clash detection follows a very consistent and deliberate coordination process that combines design models, tests them for conflicts, and resolves issues through collaboration and iteration.

Let’s run through the steps next.

Model Aggregation and Setup

Each discipline, including architecture, structure, and MEP, develops its own BIM model. These are then combined into a federated model using coordination software.

The BIM coordinator ensures all files align to a shared coordinate system, units, and version. A BIM Execution Plan defines the protocols for coordination, including naming conventions, upload schedules, and responsibilities.

Structural elements and other fixed components are modelled first, allowing flexible systems, such as mechanical and electrical, to be routed around them, thereby reducing the likelihood of initial clashes.Preliminary Checks

Before clash detection begins, each model undergoes quality assurance and control checks. Teams confirm that models are aligned, free from duplicates, and up to date to prevent false positives. This review ensures the automated detection process identifies meaningful issues rather than excessive or irrelevant clashes.

Running the Clash Detection Test

The BIM coordinator configures the clash tests within the software, selecting which disciplines or systems to compare, such as ducts against beams or pipes against ceilings. Tolerances are applied to capture clearance issues, while intentional intersections, including sleeves or openings, are excluded.

The software then performs automated checks and produces a visual report pinpointing each detected clash.Reviewing and Prioritising Clashes

The initial report may reveal hundreds of potential conflicts. The coordination team reviews and categorises them by severity, type, or location.

Structural or major MEP clashes are prioritised, while minor overlaps that fall within acceptable tolerances can be left for on-site adjustment. This process turns an automated list into actionable tasks for each responsible discipline.Clash Resolution

Designers and engineers work collaboratively to resolve high-priority clashes within the digital model. Solutions can include rerouting ductwork, adjusting beam placement with structural approval, resizing components, or modifying the construction sequence.

Each issue is logged, assigned to an owner, and tracked until resolved. Any changes requiring documentation are recorded as Technical Queries to maintain traceability.Iteration and Model Updates

After modifications are applied, the federated model is updated, and clash detection is rerun. Because resolving one issue can introduce another, this cycle continues until all hard clashes are removed and remaining issues fall within tolerance limits. Iterative checking maintains model integrity and ensures coordination accuracy.

Documentation and Sign-Off

Every clash, resolution, and approval is recorded in a clash report log. Once all critical issues are resolved, the BIM coordinator issues a final sign-off confirming the model is fully coordinated.

This record often forms part of the project’s contractual deliverables and supports procurement, fabrication, and construction sequencing with confidence.

Key Habits for Smarter, More Efficient Clash Detection

High-performing construction teams view clash detection as a strategic control process, rather than a software feature. Embedding these habits across design coordination helps reduce rework, shorten schedules, and improve cost predictability.

Integrate Clash Detection Early

Run clash tests as soon as models reach a workable level of detail rather than waiting until design completion. Early detection enables low-cost corrections before budgets, procurement, and schedules are locked in.

A DBIA case study on a $355 million project found that proactive clash detection identified about 2,000 conflicts and prevented $3.4 million in rework. This tenfold return on investment in coordination demonstrates how early integration reduces change orders, compresses delivery timelines, and enhances forecasting confidence.

Define Clear Coordination Standards

Strong coordination depends on shared standards.

Establish a BIM Execution Plan early to set file naming rules, upload cadence, and discipline responsibilities. Consistent tolerance settings ensure the software filters out minor deviations and highlights high-risk clashes first.

A clear responsibility matrix defines ownership across systems and trades. With everyone working to the same framework, coordination becomes faster, reviews are more focused, and meetings shift from administrative discussions to decision-making sessions that drive progress.

Prioritise and Manage Critical Clashes

Clash detection should be managed as a core risk control activity. Focus on structural and major MEP conflicts that can halt construction or trigger Extension of Time claims.

Group and filter clashes by severity so resources go where they create the most value. The goal is constructability, not perfection. Accept minor, flexible conflicts, such as movable ducting, where appropriate, to prevent wasted effort and maintain lean coordination.

Pro Tip

Clash detection only delivers value when resolutions reflect how the project will actually be built. Bring site supervisors and fabricators into coordination early so design decisions align with real installation constraints. The strongest models are shaped by people who understand how the work gets done, not just how it looks on screen.

Keep Models Current and Controlled

Effective coordination depends on a single source of truth.

Store and share models in a Common Data Environment with strict version control. Each discipline must upload verified updates at set intervals to keep everyone aligned.

Working from outdated models leads to duplicated effort and design drift. Controlled data management prevents previously resolved issues from resurfacing later in the construction process.

Foster Collaborative Resolution

Make coordination meetings multidisciplinary, bringing together designers, engineers, fabricators, and site supervisors. Encourage open discussion about constructability and sequencing to ensure solutions are both practical and safe. Record every resolution through Technical Queries or coordination logs to maintain visibility.

This shared accountability enhances decision-making speed, minimizes friction, and prevents the downstream cost escalation that often results from poor communication.

Leverage Data and Continuous Improvement

Digital coordination platforms provide valuable performance insight.

Analyse project data such as RFIs, Technical Queries, and variation orders to identify recurring risks and coordination gaps. Feed these lessons into future tenders and construction planning to strengthen predictability in cost and delivery.

Continuous tracking turns coordination from a reactive process into a cycle of ongoing improvement that compounds across projects.

BIM clash detection strengthens cost control and project certainty

BIM clash detection allows teams to identify and resolve design conflicts before they impact construction, reducing rework, delays, and safety risks. Embedding it into preconstruction workflows, contractors can improve coordination, protect margins, and deliver projects with greater efficiency and confidence.

Categories:

Written by

Josh Krissansen

55 articles

Josh Krissansen is a freelance writer with two years of experience contributing to Procore's educational library. He specialises in transforming complex construction concepts into clear, actionable insights for professionals in the industry.

View profileExplore more helpful resources

Pull Planning in Construction: A Practical Implementation Guide

When teams plan in isolation, handoffs are unclear, and constraints emerge too late to influence the sequence, the outcome is predictable: Construction projects slip. This reduces schedule reliability and increases...

Construction Material Takeoffs: The Hidden Lever of Profit, Precision and Project Certainty

Accurate material takeoffs protect profit by controlling the most significant variables in project delivery: material cost and consumption. Incorrect quantities mean compromised budgets, forecasts and tender pricing. From there, a...

The Essential Guide to Construction Work in Progress (WIP)

Most construction financial problems don’t explode overnight — they drift quietly until month-end, when it’s too late to fix the damage. Work-in-progress (WIP) accounting changes that dynamic. When WIP is...

Overbilling in Construction: What It Is and How to Manage It

Does the billing actually reflect the work completed? That question isn’t always asked during a smooth progress claim. It usually comes up when certification tightens, a client challenges a payment...